Why is prototype production so important?

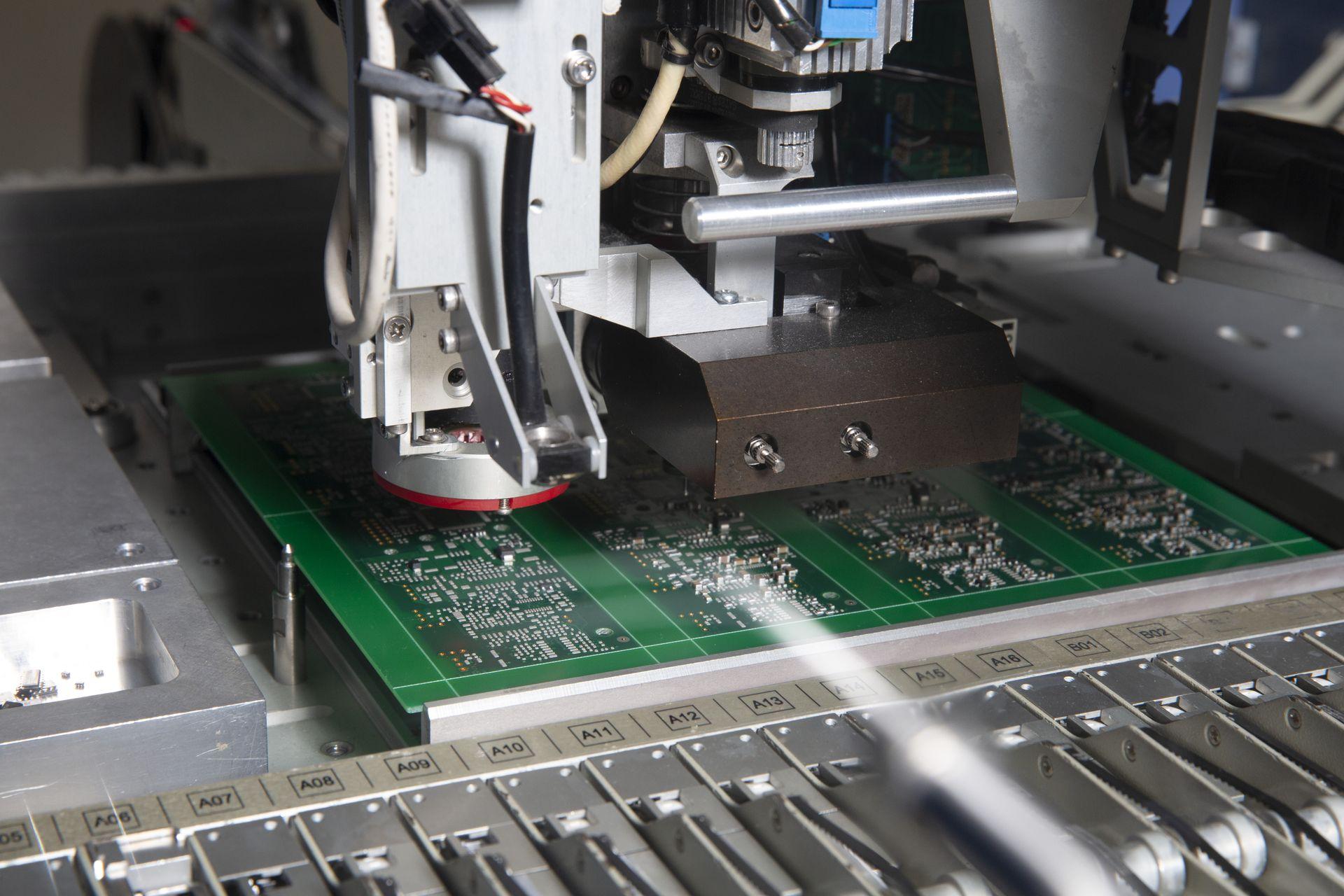

Prototype production means transforming a small batch of printed circuit boards (PCB's) into fully assembled printed circuit board assemblies (PCBA's). The assembly process includes multiple stages, typically starting in the Surface-Mount Device (SMD) production department, followed by the hand soldering department. Once the PCBA assembly is completed, the products undergo quality checks before being passed on to (embedded) software engineers for testing or assembly staff for further integration.

It is very important to involve prototype production before you start with serial production. These two production types are different stages in the manufacturing process and have distinct purposes and characteristics. It is common to undergo multiple rounds of prototype production prior to commencing the initial serial production phase (0-series production).

- Purpose

Prototype production is focused on creating a preliminary version of a product to test design, functionality and feasibility. It is used to identify and resolve design issues before full-scale manufacturing. - Volume

Typically involves producing a small number of units, at VEDS Group we recommend around 3 to 5 pieces, to validate the design. - Flexibility

Highly flexible, allowing for frequent design changes and adjustments based on testing and feedback. - Cost

Higher cost per unit due to the low volume, custom setups, and manual processes. The focus is on precision and testing rather than cost-efficiency. - Lead Time

Can have shorter lead times for initial units but may involve iterative processes that extend the overall timeline. - Quality Control

Emphasis on detailed inspection and testing to ensure the prototype meets the design specifications and performance requirements.

Specializations

- (Double-sided) SMD Assembly

We offer precise double-sided Surface-Mount Device (SMD) assembly, accommodating components on both sides of the PCB for efficient use of space and enhanced design flexibility. - BGA and FPGA Placement

Expert placement of Ball Grid Array (BGA) and Field-Programmable Gate Array (FPGA) components ensures reliable connections and performance in high-density, complex electronic designs. - Odd-Shape Components and Chips

We handle assembly of components and chips of various shapes and sizes, including irregularly shaped parts, ensuring versatile and customized solutions for unique design requirements. - Assembly of Very Small and Complex Designs

Our team specializes in assembling intricate and compact designs, providing high-precision assembly for the most demanding and detailed electronic projects. - Mounting of (Complex) Flex PCB

Expertise in mounting complex flexible PCBs, enabling compact, bendable, and lightweight circuit solutions for advanced applications where traditional rigid boards are unsuitable. - Through-Hole Assembly

We provide through-hole assembly services for components requiring strong mechanical bonds, ideal for products subjected to high stress or requiring robust electrical connections. - SMD & Through-Hole Combination

Combining SMD and through-hole assembly techniques allows us to optimize designs for performance, cost, and space, offering a flexible approach to complex electronic assemblies.

All our production staff hold the internationally recognised IPC-A-610 certificate. They are trained and periodically tested by our internal IPC trainer.

All production processes are conducted in an ESD-safe environment, protecting sensitive electronic components from electrostatic discharge and ensuring the highest level of product integrity.