When and why does your project need a mechanical engineer

Electronic and mechanical prototyping work hand-in-hand to develop functional, reliable products. In electronic prototyping, components such as microcontrollers, sensors and circuits are tested to ensure they function correctly. Mechanical prototyping, meanwhile focuses on the physical structure, using materials like plastic, metal or composites to create enclosures, frameworks and moving parts. By combining these processes, developers can test the integration of electronic components within the physical design, validating factors like fit, durability and usability. This collaborative approach is essential for iterating designs efficiently, leading to higher-quality products that are ready for production and able to meet user needs effectively.

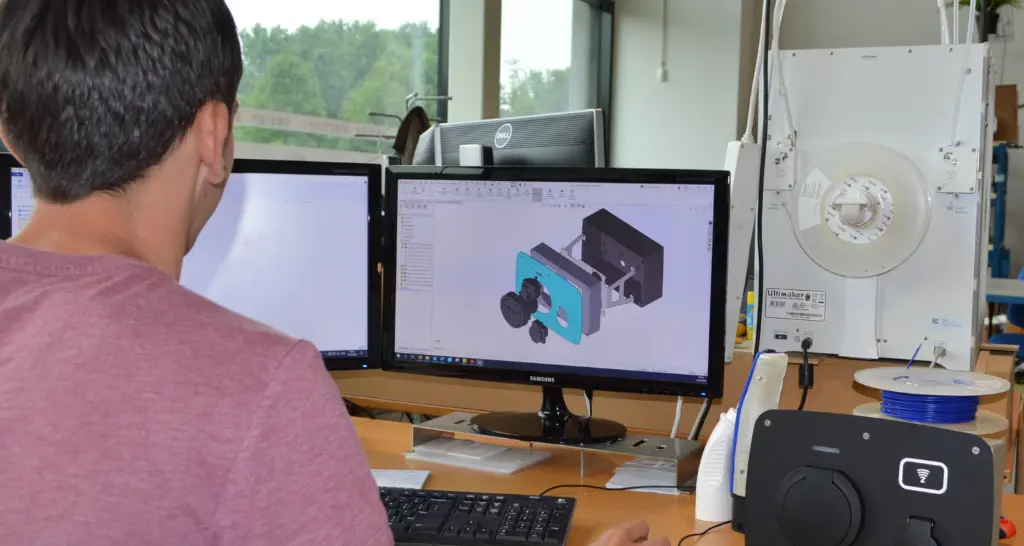

At VEDS Group, once the system architect, hardware engineers, and software engineers have provided their insights on the product to be developed, the mechanical engineer begins devising and designing the mechanical components. This design work encompasses both the internal structure and the external appearance of the product as requested by the customer. In our context, mechanical design refers to all non-electronic parts of a product.

The process begins with identifying the core problem: understanding how the product should function and its intended appearance. Key questions guide this phase, such as determining the product's size, the requirements it must meet, and other critical factors that will influence its functionality.

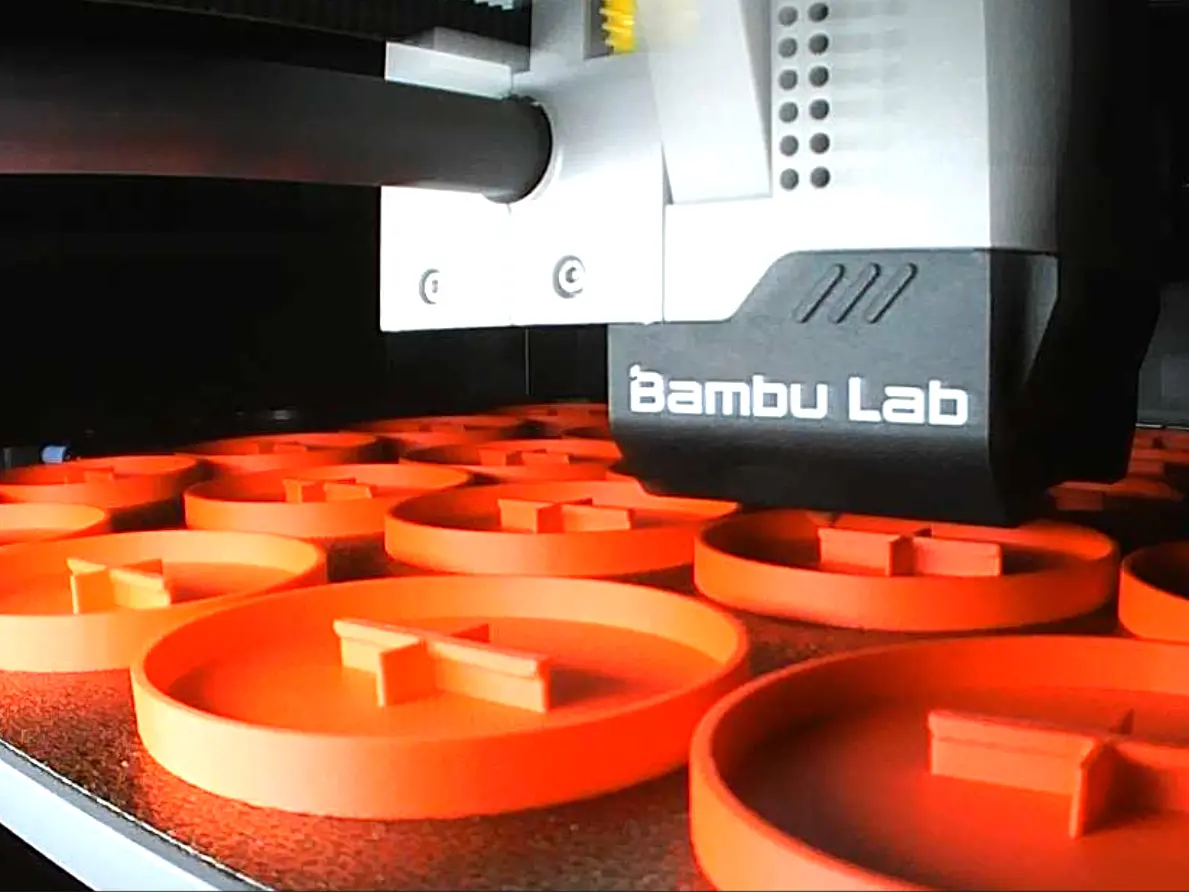

Following this initial assessment, the mechanical engineer embarks on a creative journey that ranges from rapid hand sketches to detailed designs for first 3D-printed prototypes, later replaced by for example injection-molded parts. During this process, the engineer must carefully consider various factors, including the designed hardware, the materials to be used, heat dissipation, and potential condensation within the electronic components.